There is a approach that's useful for recalibrating a tool and it is referred to as bench calibration. It's a very important system that must be executed to be able to make certain each of the parts of the Resource are functioning properly. If a Resource will not be appropriately re calibrated, it may lead to inaccurate https://www.emlcalibration.com measurement. This may result in many different troubles.

Fundamental procedure

There are plenty of methods linked to the process of recalibrating a Instrument. Calibration consists of comparing an instrument's output which has a reference instrument's. This comparison permits the measuring instrument to provide extra precise benefits.

The most basic course of action is to implement a list of Accredited gages blocks. These tend to be made to countrywide requirements. Usually, they've got a thickness of 1 mm along with a diameter of 63 mm.

Employing these gages, you must evaluate a range of masses. Normally, you will have five to ten test details. For example, it's possible you'll measure displacement, internal strain, and corner radius.

In the course of calibration, you will want to file the result that can assist you ascertain what to do future. You can also take full advantage of automated workflows to retrieve and evaluate facts.

To achieve this, you need a great calibration strategy. A nicely-published strategy will make clear the ways involved with the calibration procedure. It is going to involve the functionality requirements you might use, the approaches and applications made use of, and the reasons for that calibration.

Accreditation

If you are Functioning to provide high quality solutions, You'll have to calibrate your equipment. This method is necessary to make sure the accuracy of your respective items and processes. You may use a Licensed calibration company company to satisfy your needs.

Accredited laboratories verify their specialized and screening competence. Accreditation also offers assurance the lab has actually been independently verified by a 3rd party.

The scope of accreditation defines the areas of the laboratory and the categories of measurements it can be able to performing. It also describes the kind of kit that is used. An accrediting human body will ordinarily evaluate the standard of a lab's ecosystem and staff.

The http://edition.cnn.com/search/?text=calibration laboratory is expected to abide by a rigid set of necessities. These contain the security in the personnel as well as setting. A possibility administration procedure is additionally required.

ISO/IEC/EN 17025 is a world conventional for excellent. It demands a possibility administration program and an intensive audit of your lab. In addition, the calibration laboratory is needed to acquire an excellent assurance software.

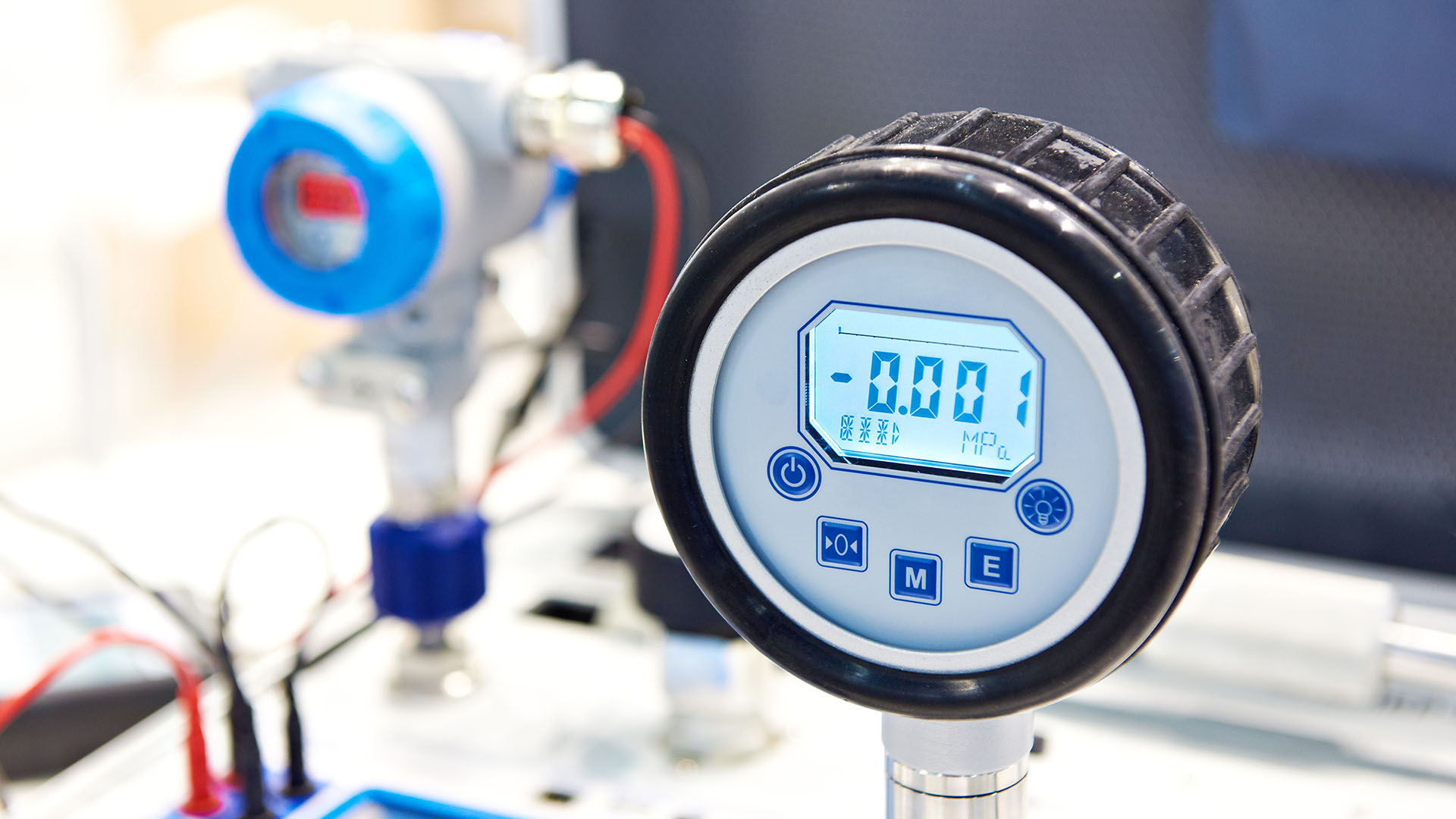

Bench calibration

When your bench calibration Instrument should be recalibrated, it is crucial to understand how to adequately carry out the process. This could be sure that the measurement is traceable to your National Institute of Benchmarks and Technologies (NIST) normal.

Calibration is the initial step to maintaining the performance of your respective measurement tools. It is also the only real way to ensure the accuracy of your products.

Bench calibration requires disconnecting your instrument from the process it is measuring, cleansing it, after which you can mounting it with a examination stand. To generally be successful, the method ought to be done inside of a managed natural environment.

A managed environment helps to reduce the whole uncertainty and the chance of mistakes. The bench ought to have access to a pressure supply. Normally, it is a hand pump. Additionally, the gauge really should be mounted in the identical orientation as the method.

In an effort to effectively calibrate your bench scale, you'll need a reference stress gauge which might be traced back to your maker. Generally speaking, you could hope the traceable pressure reference to own an precision of four times the precision of your respective product.

Traceability

Traceability is the whole process of connecting the results of the calibration to the established standards. This is the way to reduce chance affiliated with measurement machines along with the devices utilized to evaluate.

The Nationwide Institute of Specifications and Engineering (NIST) is establishing technical information on traceability. NIST also offers certifications for reference resources and measurement protocols. Furthermore, it conducts coordinated outreach applications on traceability.

The NIST Excellent Process for Measurement Services defines traceability because the relationship involving the measurements and effects of a calibration along with the proven benchmarks. If the measurements are to be traced to NIST or to a special standard, the Firm should abide by exam processes and protocol.

Traceability is really a prerequisite to meeting the necessities of globally regulatory businesses. A fantastic item can be ineffective if it has no assurance of precise measurement. In addition, it might induce hefty expenses if it fails.

Step one in traceability is to establish a series of reference. Using the Intercontinental Technique of Units, or SI, a Instrument have to be calibrated and its results are then verified and acknowledged.